One of the main responsibilities of the Walter Havighurst Special Collections is to ensure continued access to the materials in the collection. One way we achieve this is through various preservation measures to ensure the physical well being of the materials. Preservation initiatives can take many forms, from proper storage and handling, to environmental monitoring and pest control. The process of encapsulation is one such technique we use on fragile and/or important documents and papers housed in the manuscript collections.

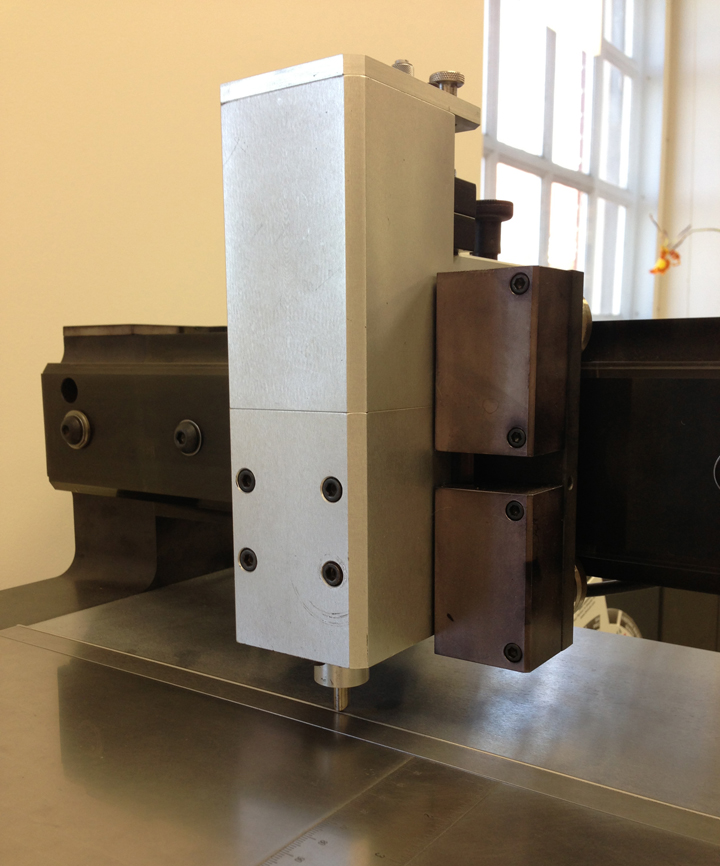

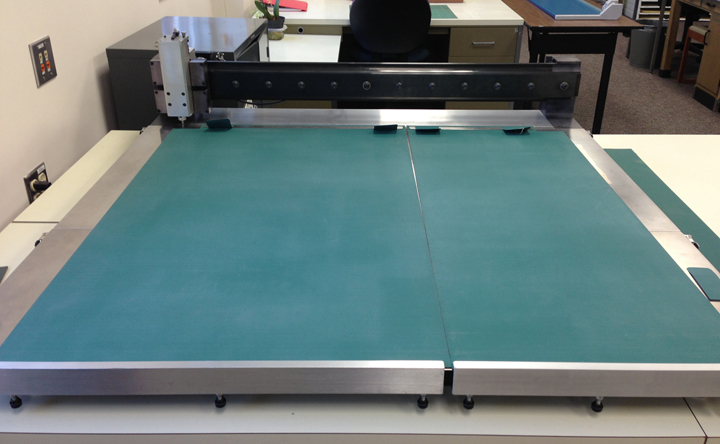

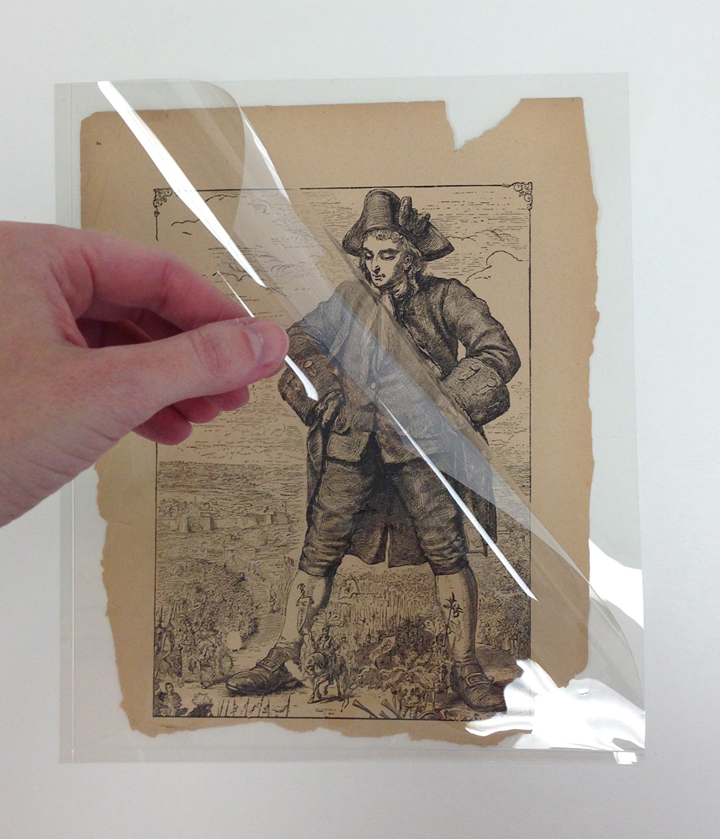

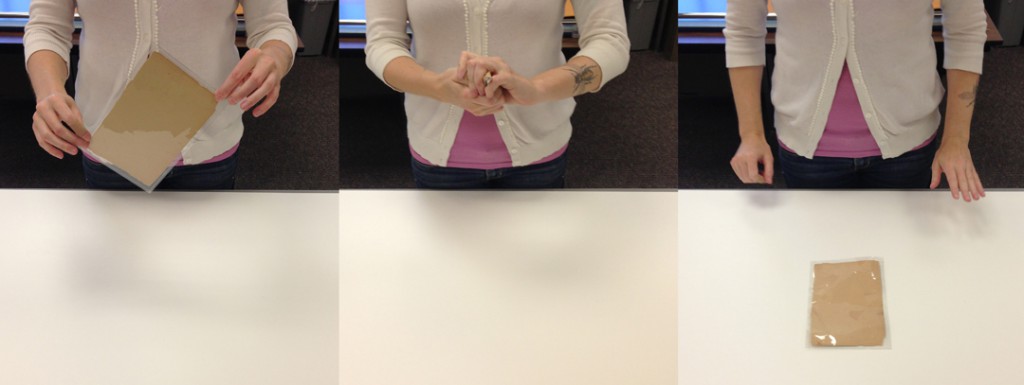

Encapsulation is when you place a flat sheet of paper between to sheets of inert polyester plastic (one particular brand of polyester is Mylar, often used as a blanket term, like Kleenex is for tissue). The sheets of polyester are then sealed on either two edges, creating an L-sleeve, or on all four edges, creating an enclosed document. The polyester can be sealed with either heat or ultrasound. When using heat an L-sleeve is usually created, as you do not want to heat the polyester with the document already inside, but rather seal the two edges and then place the document inside the sleeve. Alternatively, when using ultrasound, one can either create an L-sleeve, or fully encapsulate the document by sealing all four sides. Here at Miami we use an ultrasonic welder, usually choosing to seal all four sides of the polyester.

Double-sided tape is another method that has been utilized to create an encapsulation sleeve, although this method is not recommended. It is possible for the edges of a document to slip too close to the double sided tape, thereby damaging the document. In addition, the adhesive on the double sided tape can break down over time and spread past the tape itself, potentially damaging any document edges that come into contact with it.

Another option is to purchase pre-made polyester L-sleeves, available in a variety of standard sizes, all of which can be trimmed down to the desired size. This is a good option if only a few items need encapsulated, or if one does not have access to ultrasonic welding/heat sealing equipment. Inert polyester sleeves should not be confused with the standard clear plastic binder sleeves one finds at most office supply stores, which can break down over time and cause damage to the enclosed item.

Encapsulation should also NOT be confused with lamination. Lamination is a process by which a piece of paper is heat-fused between two pieces of plastic laminate. Not only is this process irreversible (or only reversible with solvents) it can also cause great damage to the item. As the lamination breaks down, so too does the document fused inside.

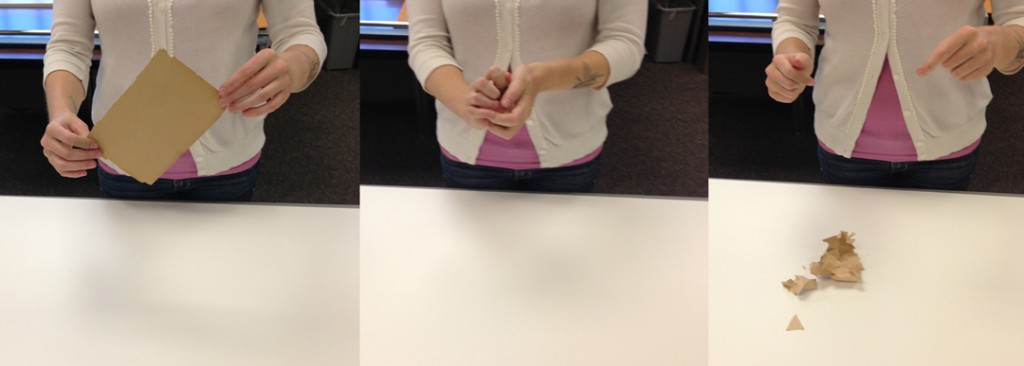

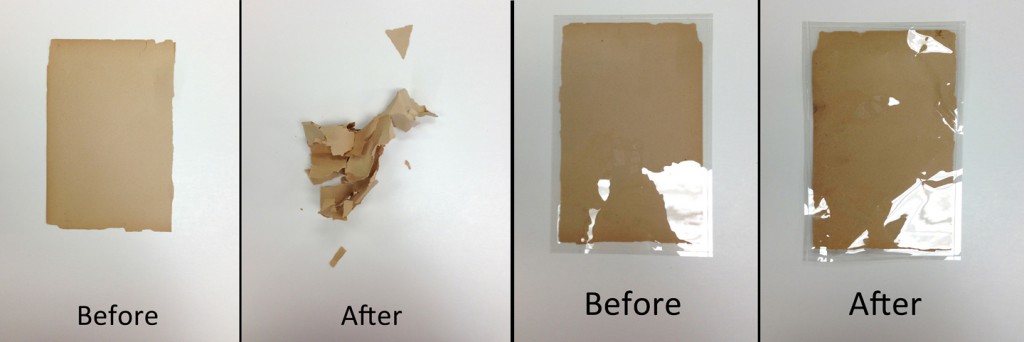

Encapsulation is an excellent way to protect documents during handling and storage. The electrostatic charge of the polyester holds the document in place, offering support, protection from fingerprints and other foreign substances, and preventing paper from crumbling or tearing while being handled. Below is a demonstration of crumpling a sheet of brittle paper, one half is crumpled as is, the other half is encapsulated, then crumpled.

While the demo may be extreme in it’s rough handling, the photos illustrate just how protective encapsulation can be. You can see quite a difference in the end result.

While encapsulation is an excellent solution for many documents, it is not a perfect solution for everything. Often times encapsulating a document creates a closed environment for the document, which can be problematic if stored in warm, humid areas. The closed environment can speed up the deterioration caused by acid inherent in the document, leading to brittle, crumbling paper. Often times items are treated with a deacidification spray before being encapsulated (although these sprays have their own limitations and drawbacks). The use of an ultrasonic welder can limit the effects of a closed environment, as the weld is not actually a solid weld, as it appears to the naked eye, but rather a series of small dots which allows for some airflow through the encapsulation environment. Another way to avoid the closed environment effect is to utilize the L-sleeve method of encapsulation. The electrostatic charge of the polyester holding the document in place makes the L-sleeve as effective as a four sided weld.

While encapsulation is an excellent solution for many documents, it is not a perfect solution for everything. Often times encapsulating a document creates a closed environment for the document, which can be problematic if stored in warm, humid areas. The closed environment can speed up the deterioration caused by acid inherent in the document, leading to brittle, crumbling paper. Often times items are treated with a deacidification spray before being encapsulated (although these sprays have their own limitations and drawbacks). The use of an ultrasonic welder can limit the effects of a closed environment, as the weld is not actually a solid weld, as it appears to the naked eye, but rather a series of small dots which allows for some airflow through the encapsulation environment. Another way to avoid the closed environment effect is to utilize the L-sleeve method of encapsulation. The electrostatic charge of the polyester holding the document in place makes the L-sleeve as effective as a four sided weld.

Another potential drawback lies in the very characteristic that makes encapsulation so effective, the electrostatic charge. Any document that contains friable media, such as charcoal, pastels, colored pencil, graphite, and even some paints such as gouache should not be encapsulated. Documents with flaking ink should also not be encapsulated. The electrostatic charge of the polyester can lift the media right off the paper, thereby causing significant damage. It is best to use an acid-free folder for these types of items. Encapsulation should also not be used for photographs.

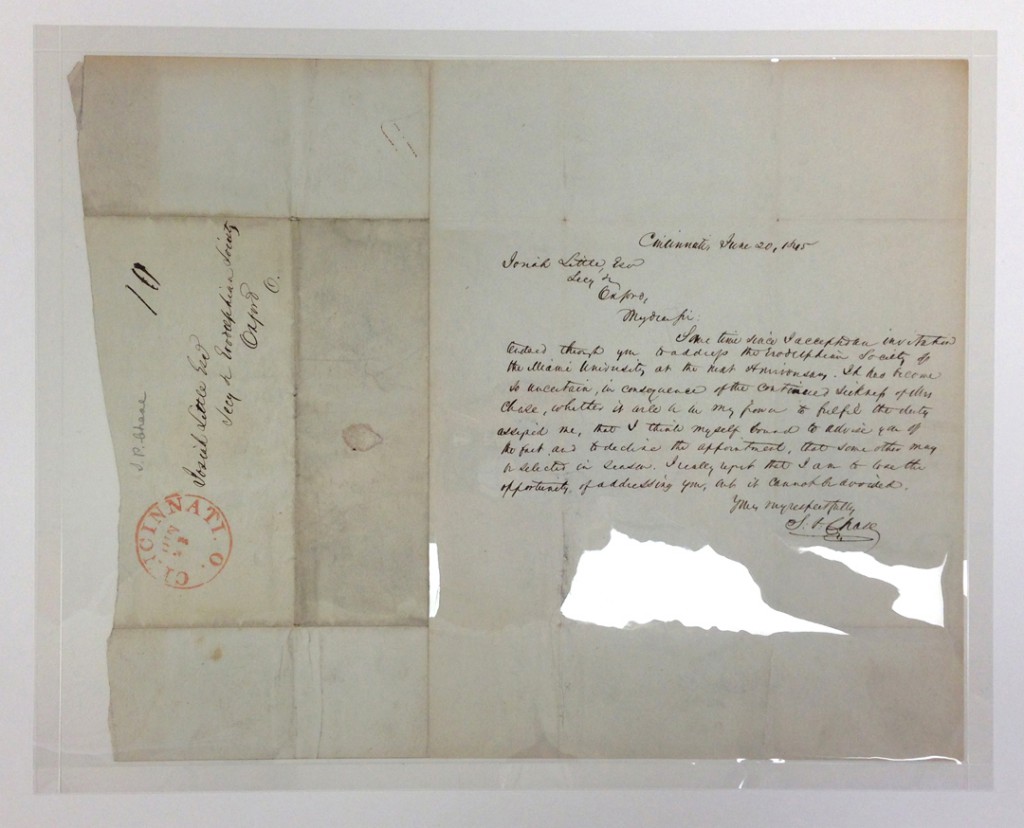

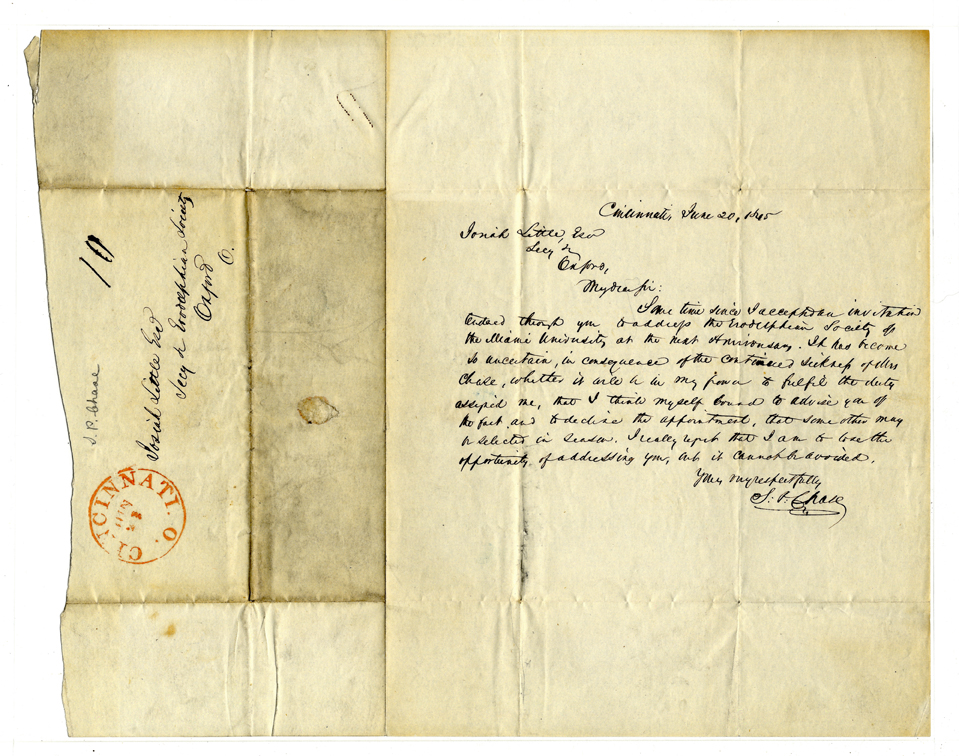

The same Chase letter, as you can see, the encapsulated item can be scanned with no visible reflections

Ashley Jones

Preservation Librarian